The leading supplier of holding time testing and residence testing in the food, beverage and dairy industry.

What is holding time/residence time?

Pasteurisation is common in many food and beverage industries and the critical component of any pasteurisation process is the holding tubes just before the divert valve, the tubes will continually hold the pasteurised product for the designed amount of time required to ensure pasteurisation has been achieved.

Holding time/residence testing on HTST, UHT and pasteurisers using saline conductivity or thermal methods

To ensure all harmful micro-organisms are killed, pasteurisation involves heating the product to international standards before it is cooled again. A combination of time and temperature is used to ensure that the taste, appearance and nutritional value of the product are not altered.

The holding time/residence time should be established as a “Critical Control Point” in any maintenance and preventative maintenance system. Without the monitoring and measuring of this critical aspect of the pasteurisation process, the likelihood of product safety hazards could occur with the possibility of damage to your brand image which can be caused by negative media attention.

Independent Integrity Inspection Limited (INDEi) provides the expertise and the solution to certify the holding time process/verification to the standards accepted by food safety directives and standards.

INDEi offers the holding time analysis system as part of the overall periodic maintenance system for plate and tubular pasteurisers and heat exchangers or as a stand-alone test complying with legislation with reliable, hygienic, accurate and trace-ability measuring solutions.

We provide a complete solution to your Pasteuriser Holding Time requirements:

We offer two different testing and inspection methods:

- The Saline Conductivity testing method.

- The Thermal Check method.

The saline conductivity testing method is the traditional international recognised method where a saline solution is injected at the starting point of the holding tube, and is detected by a conductivity probe and timed. When the solution has reached the other conductivity probe, the time is calculated.

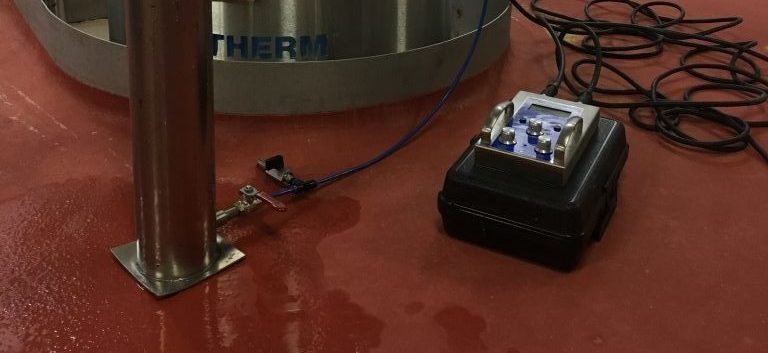

The thermal check method is a non-intrusive test and can be carried out during production. Thermocouples are placed at the beginning and the end of the holding tubes/section, a heat rise is applied to the processing plant which is detected by the Thermal Laptop and the time is calculated.

Using both the saline conductivity and thermal check methods, the Company is enabled to reproduce the results time and time again, year after year as long as the critical parameters or components have not been changed ie pump, modification of pipework, change of flow meter.

Full documentation for your quality management.

Highest levels of product purity and quality are of primary importance, particularly in such industries as the beverage, dairy, food and pharmaceutical industry. Independent Integrity Inspection Limited supports you in implementing your quality management routine by providing comprehensive test reports which are produced for every inspection activity carried out by our engineers.

Please contact us to find out more about the services we offer or fill in the online enquiry form here: